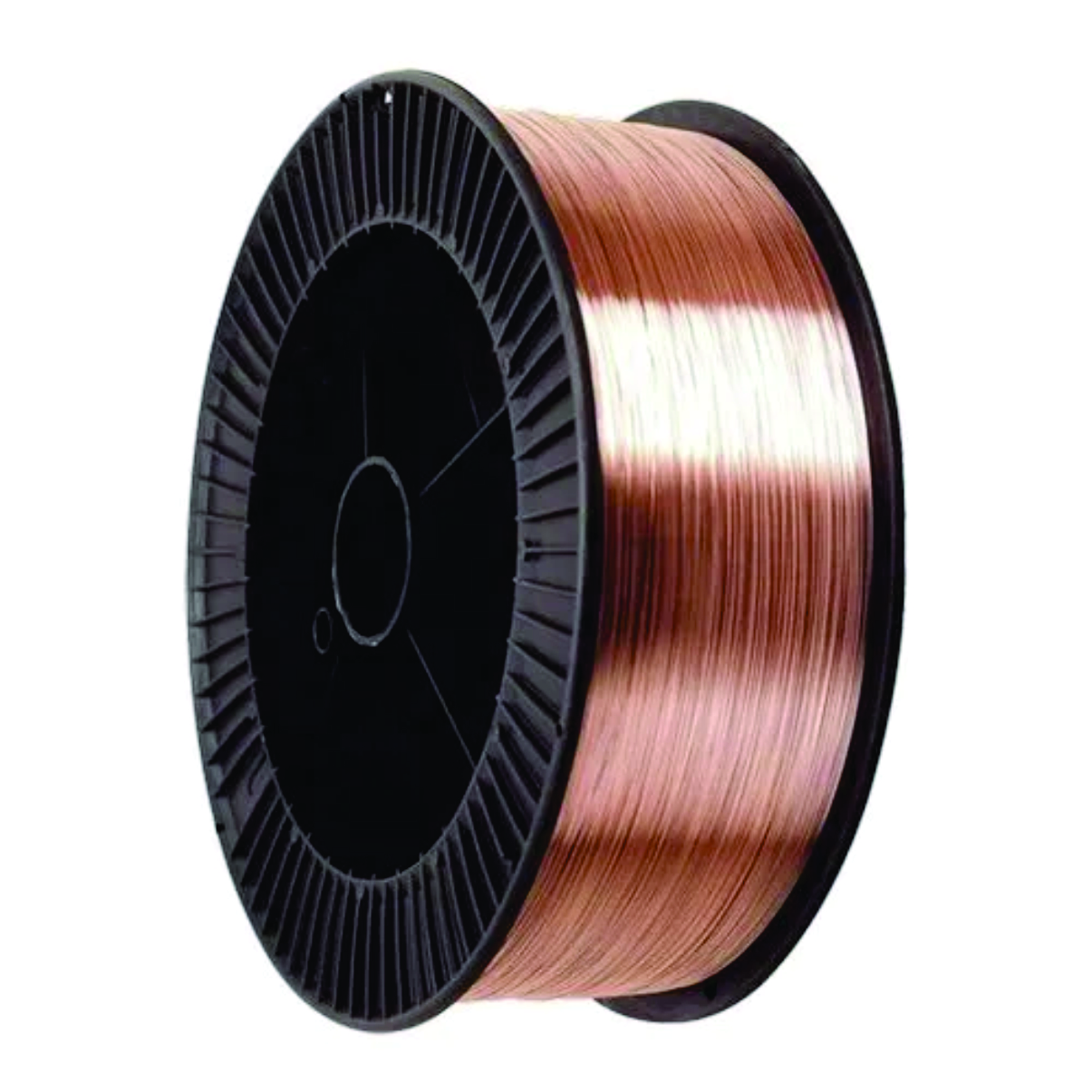

Description

The TAURUS ER70S-6 MIG wire is manufactured from high-quality deoxidised rod and finished with a copper coating to enhance shelf life, ensure excellent electrical conductivity, and minimise friction during high-speed welding. This premium-quality wire is precision layer-wound to guarantee smooth, uninterrupted feeding in both semi-automatic and fully automated welding systems.

WELDING PROCEDURE

The TAURUS ER70S-6 MIG wire is suitable for:

• Dip transfer (short arc)

• Spray arc

• Pulsed-arc transfer

Compatible with CO₂ and argon-based shielding gases.

WELDING POSITIONS

• Downhand

• Horizontal flat

• Horizontal vertical

• Vertical up

• Overhead

CLASSIFICATIONS

• AWS A5.18 ER70S-6

• SABS 145 Grade A

• EN ISO 14341 G42 2 C G4Si1

• EN ISO 636-A W 42 3 W4Si1

• EN ISO 636-B W 49 3 W4Si1

APPROVALS

• Lloyd’s Register of Shipping – Grade DXVud, BF, 2S, 2YS, H15

• American Bureau of Shipping – Grade 2SA

• TÜV Certification

| COMPOSITION | VALUE |

| Carbon | 0.07 – 0.15 % |

| Manganese | 1.4 – 1.85 % |

| Silicon | 0.8 – 1.15 % |

| Sulphur | 0.035 % Max |

| Phosphorous | 0.03 % Max |

| Copper | Typical 0.18 % 0.4 %Max |

| MECHANICAL ( with CO₂ ) | AS WELDED |

| 0.2% Proof stress | 430 MPa min |

| Tensile strength | 510 – 570 MPa |

| Elongation on 50mm | 26 min |

| Charpy V-Notch at +20°C | 110 J min |

| Charpy V-Notch at 0°C | 80 J min |

| Max Charpy V-Notch at -20°C | 47 J min |

Reviews

There are no reviews yet.