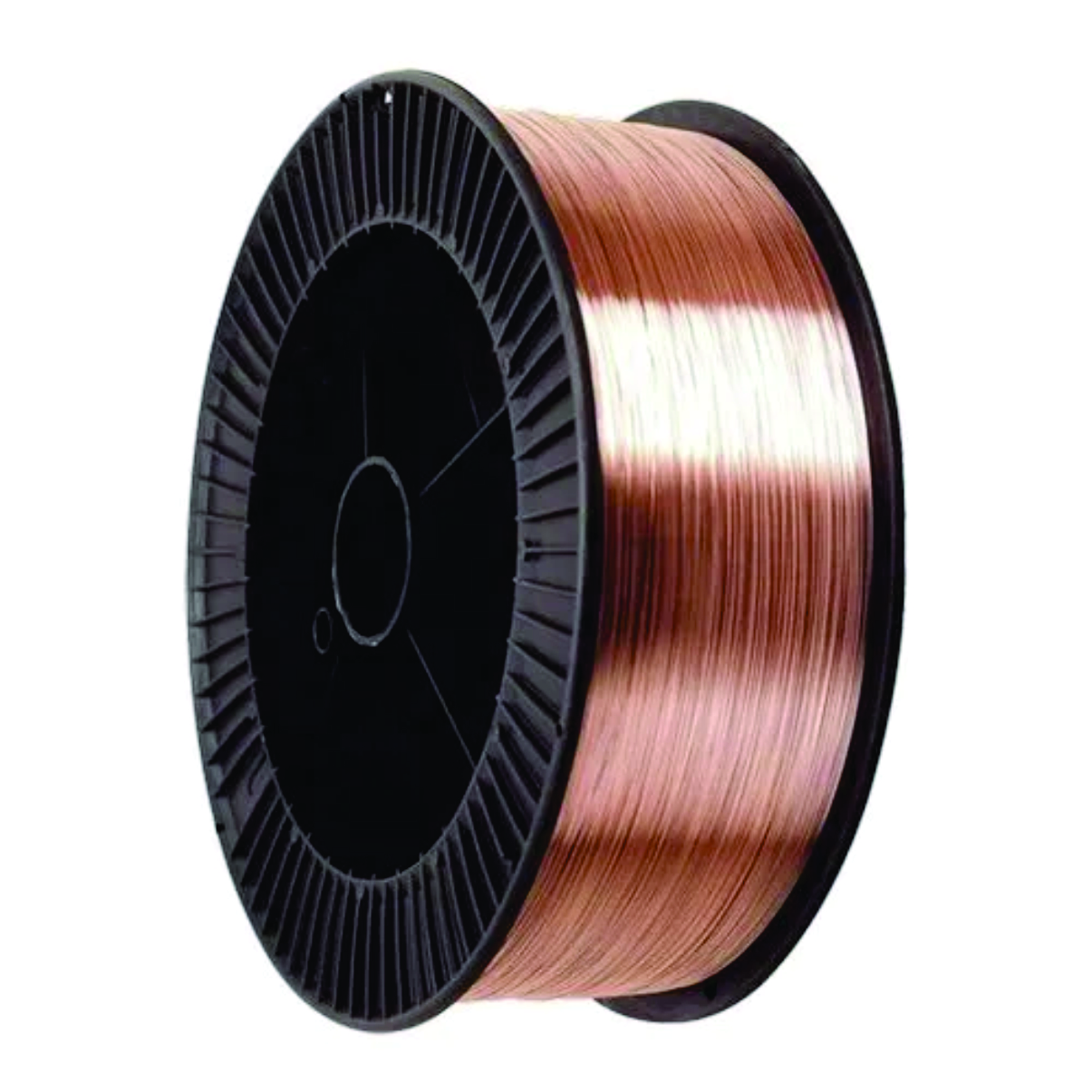

Description

The TAURUS ER70S-6 MIG wire is produced from high quality deoxidised rod. The products are copper coated for increased shelf life, which facilitates good electrical conductivity with reduced friction during high speed welding. The TAURUS ER70S-6 MIG wire is a premium quality wire which is precision layer-wound to produce positive, uninterrupted feeding in semi-automatic and automated systems.

WELDING PROCEDURE

The TAURUS ER70S-6 MIG wire is suitable for dip (short arc), spray arc and pulsed-arc transfer welding using CO2 and Argon based shielding gases.

WELDING POSITIONS

• Downhand • Horizontal flat • Horizontal vertical

• Vertical up • Overhead

CLASSIFICATIONS

AWS A5.18 ER 70s-6

SABS 145 Grade A

EN ISO 14341 G42 2 C G4Si1

EN ISO 636-A W 42 3 W4Si1

EN ISO 636-B W 49 3 W4Si1

APPROVALS

• Lloyds register of shipping grade DXVud, BF, 2S, 2YS, H15

• American Bureau of shipping grade 2SA TUV

| COMPOSITION | VALUE |

| Carbon | 0.07 – 0.15 % |

| Manganese | 1.4 – 1.85 % |

| Silicon | 0.8 – 1.15 % |

| Sulphur | 0.035 % Max |

| Phosphorous | 0.03 % Max |

| Copper | Typical 0.18 % 0.4 %Max |

| MECHANICAL ( with CO₂ ) | AS WELDED |

| 0.2% Proof stress | 430 MPa min |

| Tensile strength | 510 – 570 MPa |

| Elongation on 50mm | 26 min |

| Charpy V-Notch at +20°C | 110 J min |

| Charpy V-Notch at 0°C | 80 J min |

| Max Charpy V-Notch at -20°C | 47 J min |

Reviews

There are no reviews yet.