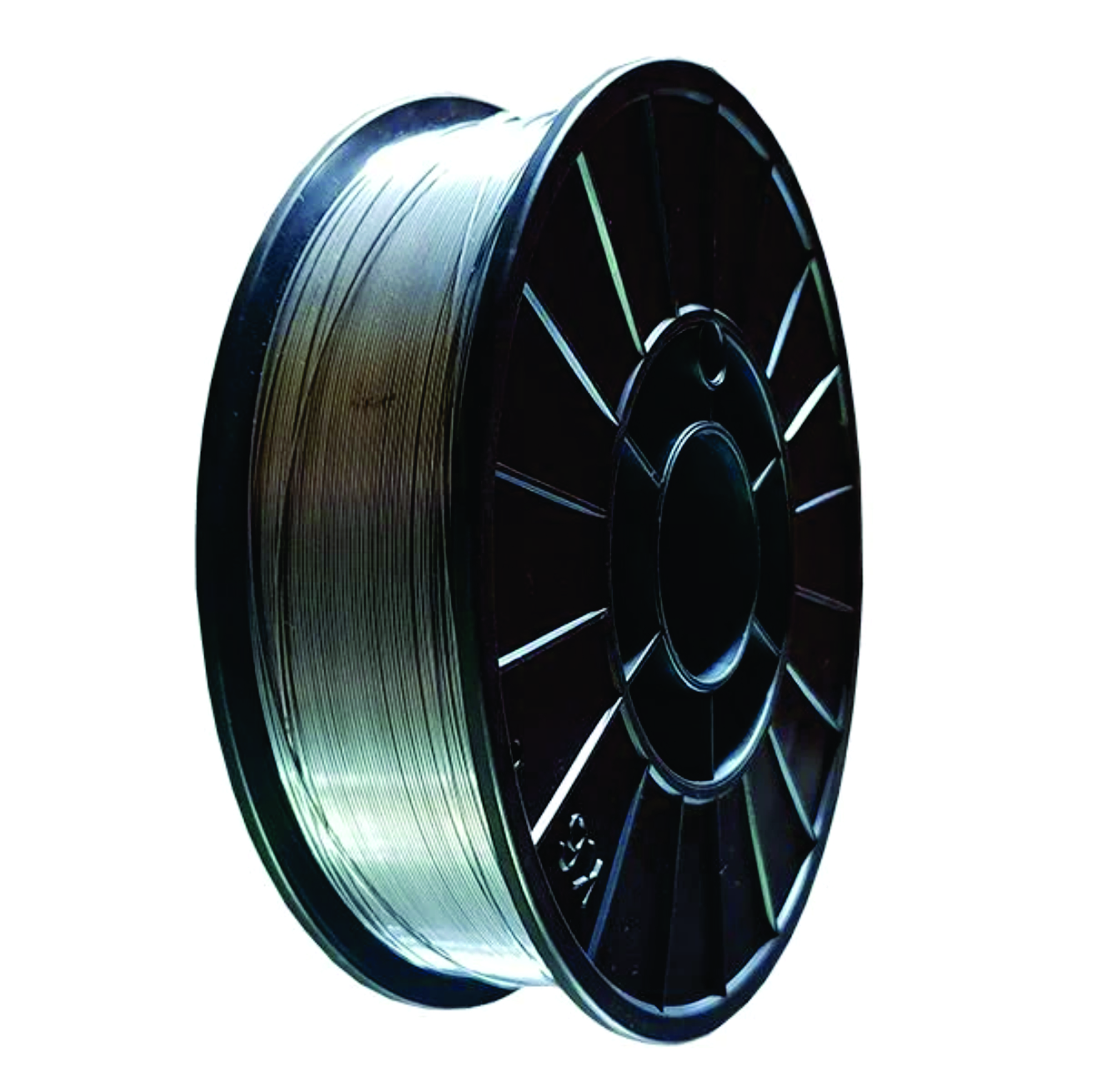

Description

TAURUS MIG 309LSI is mainly used under high dilution conditions, particularly dissimilar welds between stainless and manganese steels. There are three main areas of application: buffer layers and clad steels, dissimilar joints and similar metal Joints.

WELDING POSITIONS

• Downhand • Horizontal flat • Horizontal vertical• Vertical up • Overhead

CLASSIFICATIONS

AWS A5.9 ER309LSi

EN ISO 14343-A 23 12 L Si

EN ISO 14343-B 309L Si

| COMPOSITION | % |

| Carbon | 0.015 |

| Manganese | 1.7 |

| Silicon | 0.8 |

| Phosphorous | 0.015 |

| Sulphur | 0.005 |

| Chromium | 23.5 |

| Nickel | 13 |

| Molybdenum | 0.1 |

| Copper | 1.15 |

| Ferrite number | 12 |

| MECHANICAL | AS WELDED |

| Tensile strength | 560 MPa |

| 0.2% Proof stress | 430 MPa |

| Elongation on 4d | 42% |

| Elongation on 5d | 39% |

| Impact energy @ -20°C | 80 J |

| Impact energy @ +20°C | 100 J |

Reviews

There are no reviews yet.